सबसे लोकप्रिय उत्पाद

|

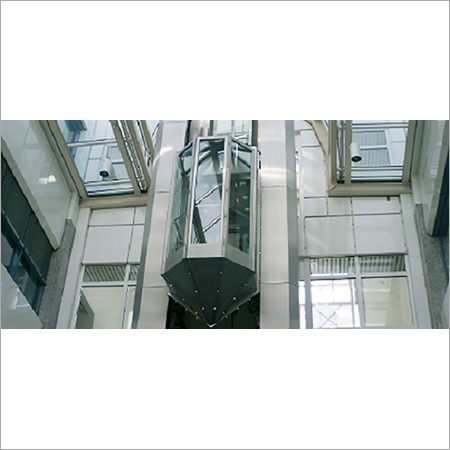

à¤à¤²à¥à¤µà¥à¤à¤° वà¥à¤°à¤¿à¤à¤¬à¤² फà¥à¤°à¥à¤à¥à¤µà¥à¤à¤¸à¥ डà¥à¤°à¤¾à¤à¤µ

à¤à¤²à¥à¤µà¥à¤à¤° वà¥à¤°à¤¿à¤à¤¬à¤² फà¥à¤°à¥à¤à¥à¤µà¥à¤à¤¸à¥ डà¥à¤°à¤¾à¤à¤µ Specification

- लोड क्षमता

- Up to 700 Kg

- फेज

- Three Phase

- कनेक्टिविटी टाइप

- Modbus RS485, CANopen

- माउंटिंग टाइप

- Wall/DIN Rail Mounted

- कंट्रोल टाइप

- Variable Frequency Control (V/F, Sensorless vector)

- सेंसर टाइप

- Integrated Encoder Feedback

- एप्लीकेशन

- Elevator/Lift motor control

- प्रोसेसर टाइप

- Digital Signal Processor (DSP)

- फ़्रिक्वेंसी

- 50/60 Hz

- रिमोट कंट्रोल

- Yes

- ऑटोमेशन ग्रेड

- Automatic

- केबल की लंबाई

- 5 meters

- ड्राइव टाइप

- AC Motor Drive

- विशेषताएँ

- Energy saving, smooth acceleration/deceleration, motor protection

- वज़न

- 6.5 Kg

- स्क्रीन साइज

- 2.8 inch LED panel

- स्पीड रेंज

- 0-150 Hz adjustable

- मटेरियल

- High grade industrial plastic and aluminium housing

- पावर

- 5.5 kW

- तापमान

- -10°C to +50°C operating range

- वोल्टेज

- 380-480V AC

- Starting Torque

- 180% at 0.5 Hz

- Input Frequency

- 45-65 Hz

- Communication Interface

- Ethernet (optional), USB

- Ambient Humidity

- 5%~95% non-condensing

- Short Circuit Protection

- Available

- Noise Level

- <50 dB

- Output Voltage

- 0-480V adjustable

- Firmware Upgradable

- Yes

- Display Type

- Multifunction digital display

- Installation Altitude

- <1000 m without derating

- Start/Stop Method

- Keypad, Remote, Automatic

- Overload Protection

- 150% for 1 minute

- Brake Chopper

- Integrated

- Cooling Method

- Forced air cooling

à¤à¤²à¥à¤µà¥à¤à¤° वà¥à¤°à¤¿à¤à¤¬à¤² फà¥à¤°à¥à¤à¥à¤µà¥à¤à¤¸à¥ डà¥à¤°à¤¾à¤à¤µ Trade Information

- Minimum Order Quantity

- 1 Carton

- आपूर्ति की क्षमता

- प्रति सप्ताह

- नमूना उपलब्ध

- Yes

- नमूना नीति

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About à¤à¤²à¥à¤µà¥à¤à¤° वà¥à¤°à¤¿à¤à¤¬à¤² फà¥à¤°à¥à¤à¥à¤µà¥à¤à¤¸à¥ डà¥à¤°à¤¾à¤à¤µ

Over the years of dedication, we have been a prominent supplier of Elevator Variable Frequency Drive to our widely scattered clients. It is precisely designed using finest of raw material and ultra modern machinery at our vendors’ unit in adherence with the prevailing industrial norms and standards. Elevator Variable Frequency Drive has gained us huge applaud from our clients for its quality, performance and easy installation for use in different industrial sectors. We offer this at highly feasible prices in the market.

Features:

Features:

- 200% OL for 3 sec,150% OL for 60%

- Ideal design for open loop elevator application

- 6 S curves for smooth operation for elvator

- Supports 200V 1-PH ARD operation as standard feature

- External break logic control by drive

- Output contactor controlby digital output & built in timer function

- Customizable 4-point V/F Pattern

- FWD/REV command check function

- PTC input with threshold settable

- Equipped with STO safety function

Superior Motor Protection and Performance

This Variable Frequency Drive safeguards elevator motors through advanced overload protection, integrated brake chopper, and sensorless vector control. Its starting torque of 180% at 0.5 Hz provides powerful lift capabilities, while smooth acceleration and deceleration minimize mechanical stress, enhancing operational reliability and motor longevity.

Intuitive Monitoring and Remote Control

The 2.8-inch multifunction digital display allows users to monitor status and parameters with clarity. With remote control options via Ethernet, USB, and communication ports including Modbus RS485 and CANopen, the VFD easily integrates with building automation systems for streamlined elevator management.

Versatile Installation with Robust Housing

Manufactured using high-grade industrial plastic and aluminum, this VFD is built for durability and safety. It supports both wall and DIN rail mounting options, handles ambient humidity up to 95% non-condensing, and maintains stable operation across temperatures from -10C to +50C, perfect for diverse environments.

FAQs of Elevator Variable Frequency Drive:

Q: How does the forced air cooling system benefit the VFDs performance?

A: The forced air cooling system effectively dissipates heat, maintaining stable temperatures and preventing overheating. This enhances the drives reliability, ensures consistent operation even during prolonged running periods, and extends its lifespan when installed in elevator systems.Q: What overload protection does the elevator VFD offer?

A: This VFD provides overload protection allowing for 150% of rated load for up to 1 minute. This feature protects the motor from damage by safely handling sudden load increases typical during elevator operation and ensures uninterrupted service in critical situations.Q: When should I upgrade the firmware, and what is the process?

A: Firmware upgrades are recommended when new features, enhanced security, or bug fixes are released. The process involves connecting the VFD via USB or Ethernet to a computer and following the manufacturers software instructions for a seamless and secure update.Q: Where can the VFD be installed for optimal performance?

A: The VFD can be installed in elevator control panels within commercial or residential buildings, provided the altitude is below 1000 meters without derating. It is suitable for humid environments thanks to its high tolerance to non-condensing humidity and robust material construction.Q: What communication interfaces does the VFD support for automation integration?

A: The VFD supports Ethernet (optional), USB, Modbus RS485, and CANopen communication interfaces. These options facilitate seamless integration with building automation systems, enable remote monitoring, and allow for flexible connectivity and control.Q: How does the integrated brake chopper help elevator operation?

A: The integrated brake chopper ensures efficient absorption and control of regenerative energy during elevator deceleration, preventing voltage spikes and improving safety. This feature contributes to smooth, reliable stopping and prolongs the drives and motors lifespan.Q: What are the main benefits of using this VFD for elevator control?

A: Key benefits include energy-saving operation, smooth acceleration and deceleration, motor protection features, quiet operation at less than 50 dB, flexible remote control options, firmware upgrade capability, and robust design for demanding elevator applications up to 700 kg load.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

|

TAC AUTOMATION PVT. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |